How To Check Capacitor?

How to check capacitance

- Use your digital multimeter (DMM) to ensure all power to the circuit is OFF.

- Visually inspect the capacitor.

- Turn the dial to the Capacitance Measurement mode.

- For a correct measurement, the capacitor will need to be removed from the circuit.

- Connect the test leads to the capacitor terminals.

What Is A Simple Way To Test Capacitors?

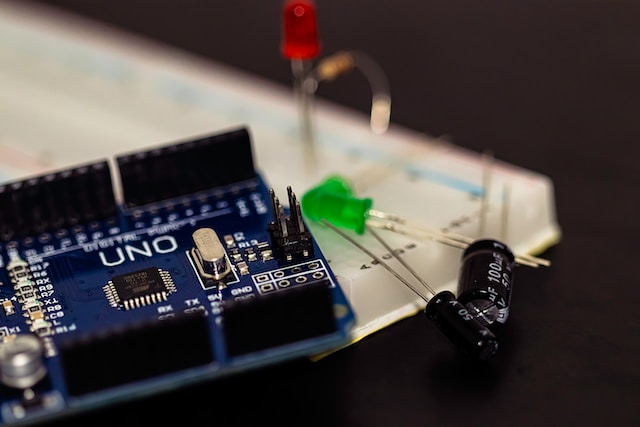

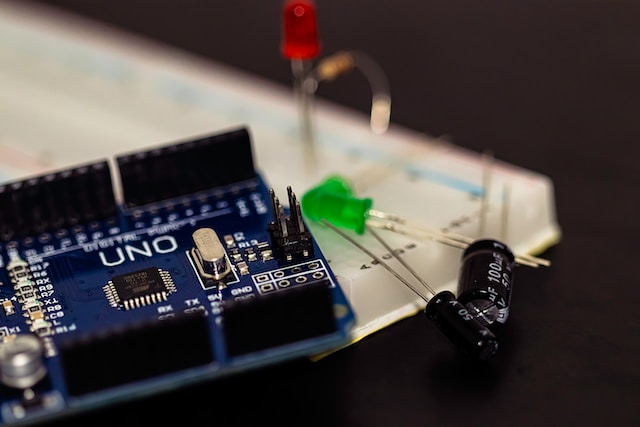

Before diving into testing methods, let’s first understand what capacitors are and their significance. A capacitor is a two-terminal electronic component designed to store electrical energy. It consists of two conductive plates separated by an insulating material known as dielectric that store electric charge when voltage is applied across their terminals; when voltage is applied across them, both plates become positively and negatively charged accordingly.

Capacitors are widely utilized in electronic circuits for many functions, including filtering, coupling, energy storage, and voltage regulation. Capacitors are capable of stabilizing voltage fluctuations by blocking direct current while permitting alternating current to pass (AC coupling), as well as smoothing out waveforms in power supplies.

Faulty Capacitors

Faulty capacitors can lead to various issues in electronic circuits, from malfunctions to complete breakdowns. Recognizing and eliminating these problematic components is vital to maintaining the integrity and reliability of your systems. Some signs that you might be dealing with faulty capacitors include:

Physically inspect your capacitor for signs of bulging or leaking. If you observe any bulging tops or any substance leaking out of the faucet, this indicates the component has failed and needs replacing immediately.

High ESR (Equivalent Series Resistance)

You can measure the equivalent series resistance of capacitors using an ESR meter; an increase in their internal resistance may affect their ability to store and discharge electrical energy effectively. If this is the case, an increase in its ESR value indicates its inadequacies as an energy store or dissipater.

Low Capacitance

Use a digital multimeter capable of measuring capacitance to assess the actual capacitance of any component. If the actual capacitance differs significantly from its labeled value, this indicates it may be defective and should be replaced as soon as possible.

Failure to Hold Charge

A properly functioning capacitor should be capable of holding onto its charge and discharging when required; any inability or excess discharging are telltale signs that something is amiss with its operation.

Now that we’ve discussed some common symptoms of faulty capacitors, let’s move on to an effective way of testing them using digital multimeters. This approach has long been utilized by electronics enthusiasts and professionals alike and should yield accurate results.

Before testing any capacitor, it’s crucial to discharge it safely to avoid electric shock. To do this, use a resistor with an equivalent resistance value greater than its capacitance; connect one end of this resistor to its positive terminal and another end to its negative terminal, and this will safely discharge any charge stored within.

Step 2: Use Your Multimeter

To measure capacitance accurately, your digital multimeter must be set into capacitance mode (usually denoted with “C”). If it has an auto-range feature, this will automatically select an appropriate range depending on its capacitance value.

Step 3: Connecting the Capacitor

To connect a capacitor, carefully connect each multimeter lead to its respective terminals of the capacitor, ensuring the positive lead connects to its respective positive terminal and vice versa. Pay special attention to polarity by connecting positive leads with positive terminals while connecting negative leads with negative terminals.

Step 4: Read Your Measurements

Once connected to a multimeter, it will measure and display capacitance values. Compare this reading against what has been indicated as labeled capacitance for your capacitor component; if its measured value falls within an acceptable tolerance (usually noted on its datasheet or capacitor specifications), then its condition should be safe to assume as optimal working order.

How Do You Test A Capacitor At Home?

Before we delve into the testing methods, let’s quickly recap what capacitors are and their significance in electronic circuits. A capacitor is a passive, two-terminal electronic component that stores electrical energy in an electric field. They are commonly used to smooth power supplies, filter signals, and store charge in electronic devices such as TVs, computers, and smartphones.

Safety First

Before attempting any testing procedures, it’s crucial to prioritize safety. Capacitors can store electrical charges even when the power is disconnected, which means they can pose a risk of electrical shock. Therefore, always ensure you have discharged the capacitor completely before handling it. To discharge a capacitor, use a resistor with appropriate resistance across its terminals and wait for a few seconds until it’s fully discharged.

Testing with a Multimeter

One of the most common and straightforward methods to test a capacitor at home is by using a digital multimeter. Follow these steps:

- Select the Appropriate Setting: Set your multimeter to the capacitance measurement mode (often denoted by “CAP” or “FARAD”).

- Discharge the Capacitor: As mentioned earlier, discharge the capacitor to ensure your safety and accurate readings.

- Connect the Multimeter: Connect the multimeter probes to the capacitor terminals. The positive probe (red) should be connected to the positive terminal, and the negative probe (black) should be connected to the negative terminal.

- Read the Value: The multimeter will display the capacitance value. Compare this value with the capacitor’s labeled capacitance to determine if it is within an acceptable range. Capacitors can have a tolerance, usually indicated as a percentage, that is considered normal.

- Charge and Re-Test: If the initial reading is inconclusive or if you suspect the capacitor is defective, you can charge the capacitor by applying voltage across its terminals momentarily and then discharge it. Re-test the capacitance to see if it falls within the specified range.

Using an ESR Meter

While multimeters can give you a rough idea of a capacitor’s health, they may not be able to identify all issues accurately. For a more in-depth analysis, an ESR (Equivalent resistance) meter can be used. ESR is a crucial factor in determining the health of capacitors, especially electrolytic capacitors. Here’s how to use an ESR meter:

- Disconnect the Capacitor: Make sure the capacitor is disconnected from the circuit board before proceeding.

- Connect the ESR Meter: Attach the ESR meter’s probes to the capacitor’s terminals. Polarity does not matter in this case.

- Read the ESR Value: The ESR meter will display the equivalent series resistance of the capacitor. A low ESR value indicates a healthy capacitor, while a high value suggests a faulty one.

- Interpreting the Results: Compare the ESR value with the manufacturer’s specifications. If the measured ESR is significantly higher than the specified range, the capacitor may need replacement.

Replacing a Faulty Capacitor

If the testing reveals that the capacitor is indeed faulty, you can now proceed to replace it. Before you start the replacement process, make sure to note down the capacitor’s specifications, such as capacitance value, voltage rating, and polarity. You can then purchase a replacement capacitor with identical specifications from a reliable electronics store.

To replace the capacitor, follow these steps:

- Safety First: Always disconnect the power supply and discharge the capacitor, as discussed earlier.

- Desolder the Faulty Capacitor: Using a soldering iron, carefully desolder the faulty capacitor from the circuit board. Be gentle, and avoid damaging nearby components.

- Install the New Capacitor: Insert the new capacitor into the circuit board and solder it in place. Make sure to observe the correct polarity (if applicable).

- Test the Circuit: After the replacement, test the circuit to ensure that it functions correctly and that the issue has been resolved.

How Long Do AC Capacitors Last?

AC capacitors, also known as air conditioner capacitors, are crucial components of any HVAC system. These small cylindrical devices store and release electrical energy to help start and run the motor that powers the air conditioner’s compressor. There are two types of AC capacitors: the start capacitor, responsible for initiating the motor’s rotation, and the run capacitor, which keeps the motor running smoothly.

The Lifespan of AC Capacitors

The average lifespan of AC capacitors can vary depending on various factors, such as usage, climate, and the quality of the capacitor itself. On average, an AC capacitor can last anywhere from 5 to 20 years. However, it’s essential to keep in mind that these estimates are not definitive, and capacitors can fail prematurely or last longer than expected.

Factors Affecting AC Capacitor Lifespan

Several factors can influence the lifespan of AC capacitors, and it’s crucial to be aware of them to ensure optimal performance and longevity.

Usage and Load

The more frequently an air conditioner is used, the more strain it puts on the capacitor. Homes in regions with scorching summers may run their AC units for extended periods, leading to increased wear on the capacitor.

Temperature and Climate

Extreme temperatures, especially high heat, can affect the capacitor’s performance and life expectancy. In regions with harsh climates, capacitors may degrade faster.

Power Surges

Electrical surges caused by lightning strikes or power outages can damage AC capacitors. Installing surge protectors can help mitigate this risk.

Quality of the Capacitor

The quality of the capacitor itself plays a significant role in determining its lifespan. Investing in high-quality capacitors can lead to longer-lasting and more reliable performance.

Common Signs of a Failing AC Capacitor

Identifying a failing capacitor early on can prevent further damage to your air conditioning system. Here are some common signs to watch out for:

Difficulty Starting the AC

If you notice your air conditioner struggling to start or experiencing delayed start-up, it could indicate a faulty start capacitor.

AC Takes Longer to Cool

A failing run capacitor may result in reduced cooling efficiency, leading to extended cooling cycles and higher energy bills.

Unusual Noises

A faulty capacitor can cause strange noises, such as humming or buzzing, during the operation of the air conditioner.

AC Shuts Off Unexpectedly

If your air conditioner frequently shuts off without warning, the capacitor may be failing, causing the system to overheat.

Visible Physical Damage

Inspect the capacitor for any signs of physical damage, such as bulging, leaking, or corrosion, which may indicate a need for replacement.

Extending the life of AC Capacitors

While the lifespan of AC capacitors is not entirely within our control, there are some steps you can take to extend their longevity and keep your air conditioning system running smoothly:

Regular Maintenance

Schedule regular maintenance and inspections with a qualified HVAC technician to detect and address any capacitor issues early.

Keep the Unit Clean

Regularly clean the outdoor condenser unit to prevent debris from affecting the capacitor’s performance.

Use Surge Protectors

Invest in surge protectors to safeguard the AC capacitors from electrical surges.

Maintain a stable power supply

Stabilize the power supply to your home by using voltage stabilizers or surge protectors, as inconsistent power can stress the capacitors.

FAQ’s

How can I visually inspect a capacitor to check for signs of damage?

You can visually inspect a capacitor for signs of damage by looking for bulging, leaking, or cracked casing. A damaged capacitor may also have a burnt or charred appearance, indicating a possible failure.

Can I check a capacitor with a multimeter?

Yes, you can use a multimeter to check the capacitance of a capacitor. Set your multimeter to the capacitance (F) setting and then connect the leads to the corresponding terminals of the capacitor. The multimeter will display the capacitance value, allowing you to determine if it matches the rated capacitance.

How can I test a capacitor to see if it is faulty or defective?

You can test a capacitor for faults or defects using an ESR (Equivalent Series Resistance) meter. A higher-than-normal ESR reading indicates a faulty capacitor that may need replacement. Additionally, a capacitance test using a multimeter can also help identify a defective capacitor with a capacitance significantly different from its rated value.

Is it safe to test a capacitor while it is still connected to a circuit?

No, it is not safe to test a capacitor while it is still connected to a circuit. Always discharge the capacitor first by shorting its terminals with a resistor or a discharged tool. After that, remove the capacitor from the circuit to perform the testing safely.

What are the symptoms of a faulty capacitor in an electronic device?

A faulty capacitor in an electronic device may cause various symptoms, including erratic behavior, failure to start, flickering lights, or audible humming sounds. In some cases, a faulty capacitor may even leak or explode, leading to visible damage.

Can I check a capacitor’s polarity with a multimeter?

Yes, you can check a capacitor’s polarity using a digital multimeter. Set the multimeter to the continuity mode (beep mode) and touch the positive (red) lead to the positive terminal of the capacitor and the negative (black) lead to the negative terminal. If the capacitor is polarized and functioning correctly, the multimeter will beep, indicating the correct polarity. If it’s a non-polarized capacitor, it will not have a specific polarity.

How To Check Capacitor?

How to check capacitance

- Use your digital multimeter (DMM) to ensure all power to the circuit is OFF.

- Visually inspect the capacitor.

- Turn the dial to the Capacitance Measurement mode.

- For a correct measurement, the capacitor will need to be removed from the circuit.

- Connect the test leads to the capacitor terminals.

What Is A Simple Way To Test Capacitors?

Before diving into testing methods, let’s first understand what capacitors are and their significance. A capacitor is a two-terminal electronic component designed to store electrical energy. It consists of two conductive plates separated by an insulating material known as dielectric that store electric charge when voltage is applied across their terminals; when voltage is applied across them, both plates become positively and negatively charged accordingly.

Capacitors are widely utilized in electronic circuits for many functions, including filtering, coupling, energy storage, and voltage regulation. Capacitors are capable of stabilizing voltage fluctuations by blocking direct current while permitting alternating current to pass (AC coupling), as well as smoothing out waveforms in power supplies.

Faulty Capacitors

Faulty capacitors can lead to various issues in electronic circuits, from malfunctions to complete breakdowns. Recognizing and eliminating these problematic components is vital to maintaining the integrity and reliability of your systems. Some signs that you might be dealing with faulty capacitors include:

Physically inspect your capacitor for signs of bulging or leaking. If you observe any bulging tops or any substance leaking out of the faucet, this indicates the component has failed and needs replacing immediately.

High ESR (Equivalent Series Resistance)

You can measure the equivalent series resistance of capacitors using an ESR meter; an increase in their internal resistance may affect their ability to store and discharge electrical energy effectively. If this is the case, an increase in its ESR value indicates its inadequacies as an energy store or dissipater.

Low Capacitance

Use a digital multimeter capable of measuring capacitance to assess the actual capacitance of any component. If the actual capacitance differs significantly from its labeled value, this indicates it may be defective and should be replaced as soon as possible.

Failure to Hold Charge

A properly functioning capacitor should be capable of holding onto its charge and discharging when required; any inability or excess discharging are telltale signs that something is amiss with its operation.

Now that we’ve discussed some common symptoms of faulty capacitors, let’s move on to an effective way of testing them using digital multimeters. This approach has long been utilized by electronics enthusiasts and professionals alike and should yield accurate results.

Before testing any capacitor, it’s crucial to discharge it safely to avoid electric shock. To do this, use a resistor with an equivalent resistance value greater than its capacitance; connect one end of this resistor to its positive terminal and another end to its negative terminal, and this will safely discharge any charge stored within.

Step 2: Use Your Multimeter

To measure capacitance accurately, your digital multimeter must be set into capacitance mode (usually denoted with “C”). If it has an auto-range feature, this will automatically select an appropriate range depending on its capacitance value.

Step 3: Connecting the Capacitor

To connect a capacitor, carefully connect each multimeter lead to its respective terminals of the capacitor, ensuring the positive lead connects to its respective positive terminal and vice versa. Pay special attention to polarity by connecting positive leads with positive terminals while connecting negative leads with negative terminals.

Step 4: Read Your Measurements

Once connected to a multimeter, it will measure and display capacitance values. Compare this reading against what has been indicated as labeled capacitance for your capacitor component; if its measured value falls within an acceptable tolerance (usually noted on its datasheet or capacitor specifications), then its condition should be safe to assume as optimal working order.

How Do You Test A Capacitor At Home?

Before we delve into the testing methods, let’s quickly recap what capacitors are and their significance in electronic circuits. A capacitor is a passive, two-terminal electronic component that stores electrical energy in an electric field. They are commonly used to smooth power supplies, filter signals, and store charge in electronic devices such as TVs, computers, and smartphones.

Safety First

Before attempting any testing procedures, it’s crucial to prioritize safety. Capacitors can store electrical charges even when the power is disconnected, which means they can pose a risk of electrical shock. Therefore, always ensure you have discharged the capacitor completely before handling it. To discharge a capacitor, use a resistor with appropriate resistance across its terminals and wait for a few seconds until it’s fully discharged.

Testing with a Multimeter

One of the most common and straightforward methods to test a capacitor at home is by using a digital multimeter. Follow these steps:

- Select the Appropriate Setting: Set your multimeter to the capacitance measurement mode (often denoted by “CAP” or “FARAD”).

- Discharge the Capacitor: As mentioned earlier, discharge the capacitor to ensure your safety and accurate readings.

- Connect the Multimeter: Connect the multimeter probes to the capacitor terminals. The positive probe (red) should be connected to the positive terminal, and the negative probe (black) should be connected to the negative terminal.

- Read the Value: The multimeter will display the capacitance value. Compare this value with the capacitor’s labeled capacitance to determine if it is within an acceptable range. Capacitors can have a tolerance, usually indicated as a percentage, that is considered normal.

- Charge and Re-Test: If the initial reading is inconclusive or if you suspect the capacitor is defective, you can charge the capacitor by applying voltage across its terminals momentarily and then discharge it. Re-test the capacitance to see if it falls within the specified range.

Using an ESR Meter

While multimeters can give you a rough idea of a capacitor’s health, they may not be able to identify all issues accurately. For a more in-depth analysis, an ESR (Equivalent resistance) meter can be used. ESR is a crucial factor in determining the health of capacitors, especially electrolytic capacitors. Here’s how to use an ESR meter:

- Disconnect the Capacitor: Make sure the capacitor is disconnected from the circuit board before proceeding.

- Connect the ESR Meter: Attach the ESR meter’s probes to the capacitor’s terminals. Polarity does not matter in this case.

- Read the ESR Value: The ESR meter will display the equivalent series resistance of the capacitor. A low ESR value indicates a healthy capacitor, while a high value suggests a faulty one.

- Interpreting the Results: Compare the ESR value with the manufacturer’s specifications. If the measured ESR is significantly higher than the specified range, the capacitor may need replacement.

Replacing a Faulty Capacitor

If the testing reveals that the capacitor is indeed faulty, you can now proceed to replace it. Before you start the replacement process, make sure to note down the capacitor’s specifications, such as capacitance value, voltage rating, and polarity. You can then purchase a replacement capacitor with identical specifications from a reliable electronics store.

To replace the capacitor, follow these steps:

- Safety First: Always disconnect the power supply and discharge the capacitor, as discussed earlier.

- Desolder the Faulty Capacitor: Using a soldering iron, carefully desolder the faulty capacitor from the circuit board. Be gentle, and avoid damaging nearby components.

- Install the New Capacitor: Insert the new capacitor into the circuit board and solder it in place. Make sure to observe the correct polarity (if applicable).

- Test the Circuit: After the replacement, test the circuit to ensure that it functions correctly and that the issue has been resolved.

How Long Do AC Capacitors Last?

AC capacitors, also known as air conditioner capacitors, are crucial components of any HVAC system. These small cylindrical devices store and release electrical energy to help start and run the motor that powers the air conditioner’s compressor. There are two types of AC capacitors: the start capacitor, responsible for initiating the motor’s rotation, and the run capacitor, which keeps the motor running smoothly.

The Lifespan of AC Capacitors

The average lifespan of AC capacitors can vary depending on various factors, such as usage, climate, and the quality of the capacitor itself. On average, an AC capacitor can last anywhere from 5 to 20 years. However, it’s essential to keep in mind that these estimates are not definitive, and capacitors can fail prematurely or last longer than expected.

Factors Affecting AC Capacitor Lifespan

Several factors can influence the lifespan of AC capacitors, and it’s crucial to be aware of them to ensure optimal performance and longevity.

Usage and Load

The more frequently an air conditioner is used, the more strain it puts on the capacitor. Homes in regions with scorching summers may run their AC units for extended periods, leading to increased wear on the capacitor.

Temperature and Climate

Extreme temperatures, especially high heat, can affect the capacitor’s performance and life expectancy. In regions with harsh climates, capacitors may degrade faster.

Power Surges

Electrical surges caused by lightning strikes or power outages can damage AC capacitors. Installing surge protectors can help mitigate this risk.

Quality of the Capacitor

The quality of the capacitor itself plays a significant role in determining its lifespan. Investing in high-quality capacitors can lead to longer-lasting and more reliable performance.

Common Signs of a Failing AC Capacitor

Identifying a failing capacitor early on can prevent further damage to your air conditioning system. Here are some common signs to watch out for:

Difficulty Starting the AC

If you notice your air conditioner struggling to start or experiencing delayed start-up, it could indicate a faulty start capacitor.

AC Takes Longer to Cool

A failing run capacitor may result in reduced cooling efficiency, leading to extended cooling cycles and higher energy bills.

Unusual Noises

A faulty capacitor can cause strange noises, such as humming or buzzing, during the operation of the air conditioner.

AC Shuts Off Unexpectedly

If your air conditioner frequently shuts off without warning, the capacitor may be failing, causing the system to overheat.

Visible Physical Damage

Inspect the capacitor for any signs of physical damage, such as bulging, leaking, or corrosion, which may indicate a need for replacement.

Extending the life of AC Capacitors

While the lifespan of AC capacitors is not entirely within our control, there are some steps you can take to extend their longevity and keep your air conditioning system running smoothly:

Regular Maintenance

Schedule regular maintenance and inspections with a qualified HVAC technician to detect and address any capacitor issues early.

Keep the Unit Clean

Regularly clean the outdoor condenser unit to prevent debris from affecting the capacitor’s performance.

Use Surge Protectors

Invest in surge protectors to safeguard the AC capacitors from electrical surges.

Maintain a stable power supply

Stabilize the power supply to your home by using voltage stabilizers or surge protectors, as inconsistent power can stress the capacitors.

FAQ’s

How can I visually inspect a capacitor to check for signs of damage?

You can visually inspect a capacitor for signs of damage by looking for bulging, leaking, or cracked casing. A damaged capacitor may also have a burnt or charred appearance, indicating a possible failure.

Can I check a capacitor with a multimeter?

Yes, you can use a multimeter to check the capacitance of a capacitor. Set your multimeter to the capacitance (F) setting and then connect the leads to the corresponding terminals of the capacitor. The multimeter will display the capacitance value, allowing you to determine if it matches the rated capacitance.

How can I test a capacitor to see if it is faulty or defective?

You can test a capacitor for faults or defects using an ESR (Equivalent Series Resistance) meter. A higher-than-normal ESR reading indicates a faulty capacitor that may need replacement. Additionally, a capacitance test using a multimeter can also help identify a defective capacitor with a capacitance significantly different from its rated value.

Is it safe to test a capacitor while it is still connected to a circuit?

No, it is not safe to test a capacitor while it is still connected to a circuit. Always discharge the capacitor first by shorting its terminals with a resistor or a discharged tool. After that, remove the capacitor from the circuit to perform the testing safely.

What are the symptoms of a faulty capacitor in an electronic device?

A faulty capacitor in an electronic device may cause various symptoms, including erratic behavior, failure to start, flickering lights, or audible humming sounds. In some cases, a faulty capacitor may even leak or explode, leading to visible damage.

Can I check a capacitor’s polarity with a multimeter?

Yes, you can check a capacitor’s polarity using a digital multimeter. Set the multimeter to the continuity mode (beep mode) and touch the positive (red) lead to the positive terminal of the capacitor and the negative (black) lead to the negative terminal. If the capacitor is polarized and functioning correctly, the multimeter will beep, indicating the correct polarity. If it’s a non-polarized capacitor, it will not have a specific polarity.